About Roto Moulding

In the plastic industry, there are mainly three types of processes Widley uses: injection moulding, blow moulding & Extrusion moulding. The main disadvantage of these process is high machine & mould die cost.

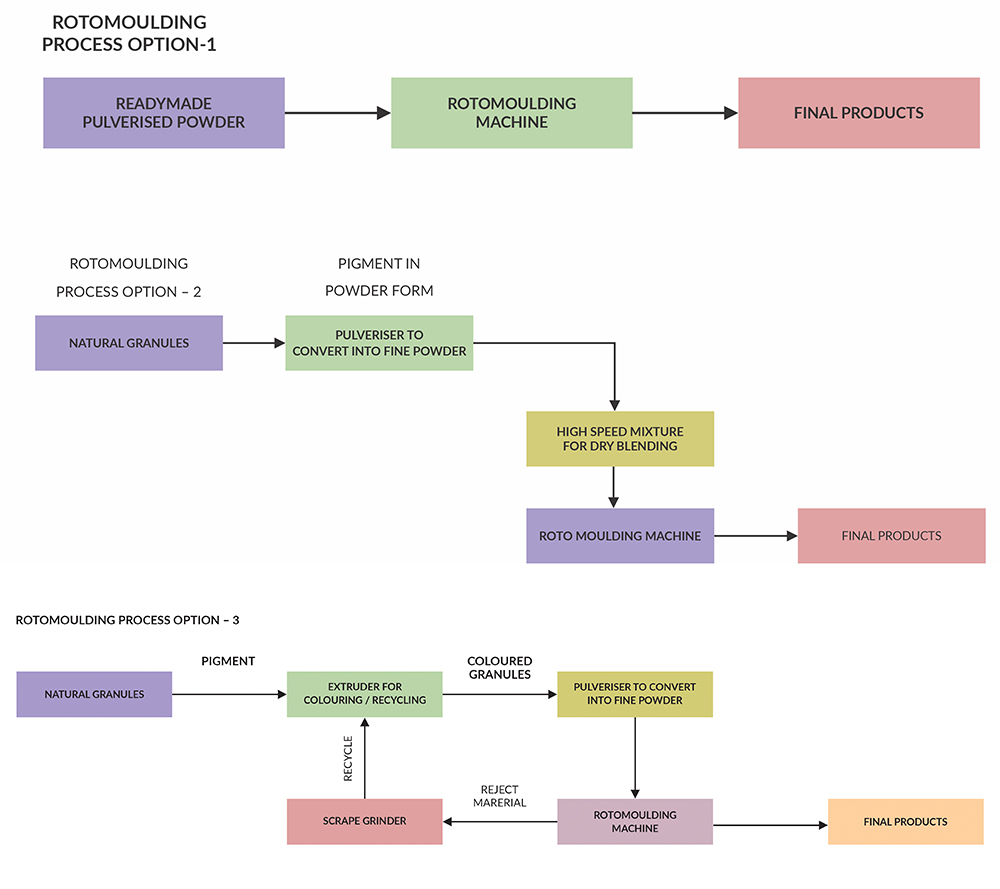

Rotomoulding process is widely used to make small- or large-sized hollow & Seamless products.

Rotational molding also known as rotomolding or roto casting. Roto moulded product is a thermo plastic products.

Rotomoulding process passes through mainly 4 stages as below Loading material heating.

The main advantage of Rotational moulding process is as below

- Hollow plastic products can be made with low levels of residual stresses

- High tensile strength, seamless product, equal wall thickness and law processing cost.

- Mould or die cost is not too much expensive

- There is no material wastage in the process. almost full charge of material is consumed in making the part

- It is possible to make multilayer products

- Different types of products can be moulded together on the one machine

- Inserts for inlet & outlet are relatively easy to mould in.

Rotomoulding product can deliver high quality & more durable parts at competitive prices. Rotational molding is best known for the manufacture of water storage tanks but it can also be used to make Furniture articles like chair, stool, table. Instead of water storage purpose, Roto moulded products are also popular in various industries like.

Years of Experience

0

+

Worldwide project / Annum

0

+

Moulds From SS-MS / Annum

0

+